INTRODUCTION:

Youbond corrugation to corrugation laminating machine, a customized model special for

the corrugation manufacturer, which fills a vacancy of the laminating equipment in the

world. Its low investment, small occupy and easy set-up is a good complement to the large

corrugation production line. This machine is easy handling, when set up the sheet size, all

machine parts will adjust automatically, which completely realizes the intelligent operation.

CHARACTERISTICS:

01. Max Speed 10000sheets/hour

02. Fully intelligent automation

03. Auto adjustment of replace different paper

04. Curve Speed positioning make sure accuracy

05. The latest technology of intermittent positioning

06. Bottom and top sheet automatic tracking system

07. Bottom paper left and right all course correction

08. Top sheet left and right all course correction

09. Intelligent detection paper length

10. Intelligent fault display and alarm system

11. Intelligent glue supply recovery system

12. Intelligent cleaning water cycle system

13. Bottom paper bending and pressing device

14. Bottom paper suction power adjust device

15. America MAC retractable air suction

16. Bottom paper belt automatic cleaning device

17. The most advanced electrical control system

18. Working type pre stack paper lifting device

19. All stainless steel glue roller configuration

20. Anti rejection glue protective device

21. Max speed 10000 sheets/hour

SPECIFICATION:

| Model | YB-1650G |

| Max Sheet Size | 1650×1450mm |

| Min sheet Size | 550×550mm |

| Max Speed(sheets/hour) | 10000sheets/hour |

| Fitting Precision | ±0.5mm |

| Measurement | 10×2.4×2.4M |

| Machine Weight | 7500kg |

| Machine Power | 22KW/380V |

|

Top paper |

A/B/C/E/F Two layers corrugated paper |

| Bottom paper |

A/B/C/E/F Two layers corrugated paper |

CONFIGURATION LIST:

|

Touch Screen |  |

AC Servo driver |

| Place of origin:Germany | Place of origin:Japan | ||

| Brand:SIEMENS | Brand:YASKAWA | ||

|

Servo Motor |  |

Frequency Converter |

| Place of origin:Japan | Place of origin:Japan | ||

| Brand:YASKAWA | Brand:YASKAWA | ||

|

PLC |  |

Main Motor |

| Place of origin:Germany | Place of origin:Taiwan | ||

| Brand:SIEMENS | Brand:CPG | ||

|

Drive Chain |  |

Synchronous Belt |

| Place of origin:Germany | Place of origin:Germany | ||

| Brand:IWIS | Brand:CONTINETAL | ||

|

Bearing |  |

Suction Belt |

| Place of origin:Japan | Place of origin:Japan | ||

| Brand:NSK | Brand:NITTA | ||

|

Tension |  |

Vacuum Pump |

| Place of origin:Switzerland | Place of origin:Germany | ||

| Brand:ROSTA | Brand:BECKER | ||

|

Contactor |  |

Solenoid valve |

| Place of origin:France | Place of origin:USA | ||

| Brand:Schneider | Brand:MAC | ||

|

Push Button |  |

Low Voltage |

| Place of origin:France | Place of origin:France | ||

| Brand:Schneider | Brand:Schneider | ||

|

Spring |  |

Linear Rail System |

| Place of origin:Japan | Place of origin:Taiwan | ||

| Brand:DAIDO | Brand:HIWIN |

BRANCH INTRODUCTION:

1. TOP/BOTTOM PAPER FEEDING

Use imported Servo motor electric controlling system, with Japan NITTA suction belt to

make suction power inverter, and belt cleaned by water roller; Patented technology to

ensure corrugate and cardboard goes out smoothly and simple operation.

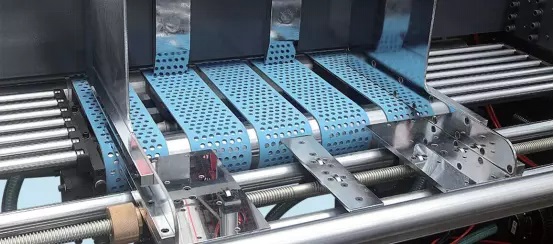

2. POSITIONING PART

Servo control of the intermittent fixed position, in the process of positioning, positioning

gauge work as” start – speed up – trackingspeed reduction-stop ” curve speed run, make

sure positioning more accurate.

3.SIDE POSITIONING

Left and right side synchronous block complete the accurate positioning, both top sheet

and bottom paper are equipped with accurate positioning device on left and right.

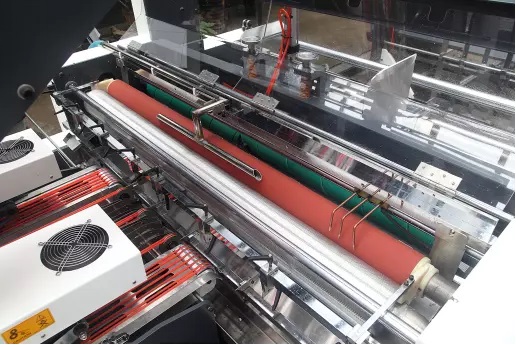

4.GLUE ROLLER

Stainless steel roller, never rust, after narrowly grinding, guaranteed the minimum

amount glue coated evenly. Down roller be cleaned by water roller.

5.TRANSMISSION

With imported double teeth belt drive and Switzerland ROSTA tension device ensure

the drive accurate, stable and low noisy.

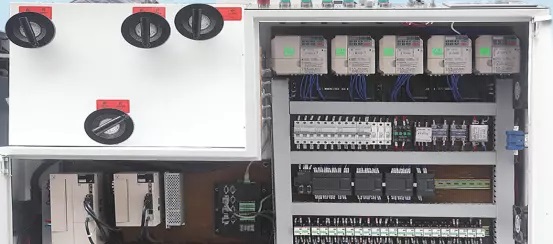

6.ELECTRICAL SYSTEM

Designed in the accordance with European CE requirement, ensure machine stability,

high efficiency and low failure. Using man-machine interface and PLC combination,

display all the information, such as warning, error detect, failures, and operating

speed, etc on the screen at a glance.