THREE IN ONEFLUTE LAMINATING MACHINE

简介 INTRODUCTION:

为印刷纸与瓦楞纸之间快速贴合利器,全机设计由三台自动送纸机(即印刷送纸机及两层瓦送纸机),两组涂胶,两组贴合主机,一组压合输送机组成,适合印刷纸与 A+A 瓦,A+B 瓦,A+E 瓦,B+A 瓦,B+B 瓦,B+E 瓦,E+A 瓦,E+B 瓦,E+E 瓦,瓦楞可以任意交换,也可作为印刷纸与 A B E 瓦为 3 层值班,还可瓦楞纸与瓦楞纸贴为四层瓦楞纸板,为印刷工序加工设备中,运转精确,操作迅速之高效能机组,给客户带来节省人力的利器。

A workable mechanical laminating machine, for printed cardboard and corrugated paper laminating machine, the whole machine is made up of 3 automatic feeding part (Top sheet feeder and 2 corrugated paper feeding part), two parts of gluing, two parts of laminating, one part of pressing conveyor. Suitable for the laminating of cardboard to A flute+A flute,A

flute+B flute,A flute+E flute,B flute+A flute,B flute+B flute,B flute+E flute,E flute+A

flute,E flute+B flute,E flute+E flute, corrugated could be changed as needed. It could also laminate cardboard to single flute to make 3ply sheet. And also for the lamination of corrugated to carrugated to 4 ply corrugated paper. A good machine for the printing process,good accuracy and quick operation, labor and time saving.

1. 卡纸送纸机 TOP FEEDER (FOR CARDBOARD)

川流式送纸风头

风头配备 4 组前进吸咀,及 2 组上下吸咀异常刹车功能及警铃装置

Four sets of foreheading suckers ensuring smooth feeding , and two sets of picking suckers. Emergency stop control for double sheet, a missed sheet or misaligned sheet. Alarm for error.

2. 坑纸(中下)送纸机 CORRUGATED PAPER(MIDDLE AND LOWER) FEEDER

可中下各控制任意一组出纸

单张式底部出纸,附强力吸风泵

配备 14 组吸风皮带(各 7 组),吸力强,送纸顺

Could control either part of the corrugated feeding part to feed sheet Single corrugated bottom feeding, with strong suction power

Equipped with 14 sucking belts ( 7 for each),strong suction and smooth feeding.

3. 收纸输送台 PAPER COLLECTOR

行进中得依弹性,顶靠纸边前进,送纸平稳

前规共 20 组(前 8 组,后 12 组),由左右链条平稳带动,由如叼牙式咬纸前进,推纸准确上纸,下纸之进退调整由“相位调整器”控制,可精准调整尺寸,贴合误差达±1.5mm

Moving in line with elasticity,moving forward on the edge of the sheet, smooth and stable

Total 20 front gauges(8 on front and 12 on the back), driven smoothly by the left and right chains, bite type moving forward, pushing the paper in an accurate way

The moving of the top sheet and bottom sheet is controlled by the “relative position controller”, it could adjust the size accurately, the accuracy was within the ±1.5mm.

4. 贴合部及涂布油头 LAMINATING PART

前贴合部适合 A+A 瓦,A+B 瓦,A+E 瓦,B+A 瓦,B+B 瓦,B+E 瓦,E+A 瓦,E+B 瓦,E+E 瓦,可任意交换,也可单张通过后贴合部与前贴合好之瓦楞贴合,也可印刷纸与单张瓦楞贴合经上光覆膜后之印刷品,不影响贴合速度,一般速度为 0-80 张/分,

油头结构由 4 支辊筒组成,上方辊筒分为涂布辊筒及计量滚筒,涂布辊筒下方与压力辊筒连接,计量辊筒能有效控制胶水之厚薄,胶水借涂布辊筒之表面,涂于瓦楞纸之上,并由压力辊筒之压力控制,将瓦楞之辗转前进,与上纸贴合。

The front laminating part could handle A flute+A flute,A flute+B flute,A flute+E flute,B flute+A flute,B flute+B flute,B flute+E flute,E flute+A flute,E flute+B flute,E flute+E flute, the laminated flute could exchange to each other. And it could laminate the cardboard to one flute, the top sheet could be the filmed and coated paper, and no different to the speed,normally the speed is 0-80sheet/min. The glue part is made up of 4 rollers, the upper ones are glue roller and metering roller, the down is pressure roller, the metering roller could control the density of the glue, glue painted on the corrugated paper and controlled by the pressure roller, make the corrugated move forward and laminated with the top sheet.

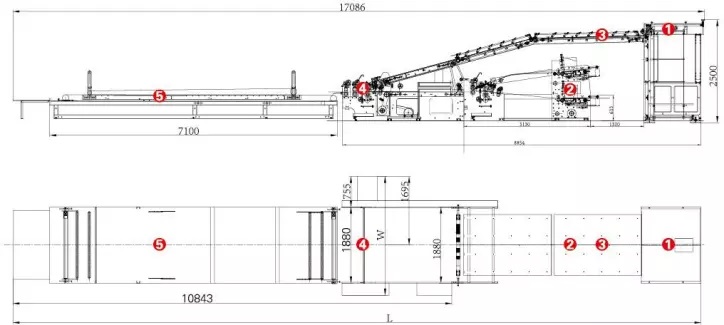

5. 基地示意图 FOUNDATION LAYOUT

|

机器型号 Model YB-1450E YB-1650E |

||||

|

最大纸张 |

Max sheet size |

1450*1100mm |

1650*1100mm |

|

|

最小纸张 |

Min sheet size |

400*400mm |

400*400mm |

|

|

面纸厚度 |

Top sheet thickness |

150-800GSM |

150-800GSM |

|

|

底纸厚度 |

Bottom sheet thickness |

0.5-10mm 0.5-10mm |

||

|

最快时速 |

Max speed( sheets/hour) |

80/min |

80/min |

|

|

贴合精度 |

Fitting precision |

±1mm |

±1mm |

|

|

外型尺寸 |

Dimensions |

15.1*2.45*2.6M |

15.1*2.65*2.6M |

|

|

机器重量 |

Machine weight |

8800kgs |

9800kgs |

|

|

机器电力 |

Machine power |

28HP/380V |

30HP/380V |

|